Polytetrafluoroethylene (TEFLON) is a kind of excellent solid lubricating materials, it has a low friction coefficient and good chemical stability and thermal stability, but the wear resistance of TEFLON was poor. At present, people have used different kinds of packing to filling modification of PT FE, and the friction and wear properties of TEFLON composites are a lot of research, but the quenching effect on tribology properties and the mechanical properties of TEFLON composites research has yet to see detailed report. This paper uses the polyimide, polystyrene grease, CdO, Cu powder, glass fiber and carbon fiber, etc. Filling modification of TEFLON, using M M – 200 wear testing machine of TEFLON composites under the condition of dry friction the friction and wear properties are studied, and probes into the impact of quenching process of TEFLON composites tribological properties and the mechanical properties.

Experimental section

To Cu, Pb, CdO powder, graphite (Gr), glass fiber (GF) and carbon fiber (CF), polyimide (PI) and polystyrene resin (Ekonol) (particle size is less than 76 microns) at a certain volume is added to the TEFLON powder (size 39 microns), after mixing cold pressing molding, then free sintering in air, some of these samples quenching process. Sample size is 30 mm *7 mm*6 mm, dual for 45 # steel ring diameter of 40 mm, samples and 45 # steel ring surface are made of 900 # water sand paper polishing burnish.At room temperature, the dry friction condition, use M M – 200 type abrasion tester on friction and wear properties of TEFLON composites is evaluated. Before each test, the sample and dual surface with acetone tampons scrub clean, and dry in the air. This experiment chooses the load is 200 N, at the rate of 0. 42 m/s, the friction and wear test time is 120 min. Wear in grinding crack width gauge on the surface of the sample after test. By measuring the friction moment, and then calculate the coefficient of friction, the friction coefficient within 60 min after taking average. Hardness test carry out on burawoy microhardness meter. Tensile properties in tension test machine for L J500 type, sample size according to the provisions of the GB/T 1040-92 with type I sample.

The results and discussion

Tab.1 shows the friction and wear properties of TEFLON composites and mechanical properties of the test results. We can see that almost all packing can reduce the wear and tear of the TEFLON composite material, greatly improve the TEFLON abrasion resistance of the composite material.At the same time, the addition of filler were improved in different degree hardness of TEFLON composites, but decreased the tensile strength of the TEFLON composite materials (except for # 5 samples) and elongation. In this experiment chooses packing, polystyrene resin has a good damping effect, so that the eps grease filling of the two kinds of TEFLON composites (# 2 and # 3 samples) has good abrasion resistance, but the two PT FE composite materials tensile strength is small. Whereas cdos reduces the friction coefficient of TEFLON composites, which makes the CdO filling two kinds of TEFLON composites (7 # and 8 #) sample has good friction performance, but the two poor wear resistance of TEFLON composites. Carbon fibers and graphite filled TEFLON composite material friction and wear properties of the samples (# 13), though poor, but the tensile strength and elongation are larger. And Cu powder and carbon fiber filled PT FE composite samples (5 #) composite friction, abrasion and mechanical performance is good. In Fig. 1 and Fig. 4 shows the amount of PI to PT FE friction coefficient of the composite material, grinding crack width, the influence of the elongation and tensile strength. From Fig. 1, you can see that PI filling increases the PT FE composite material, the friction coefficient and friction coefficient of TEFLON composites basically as the PI content increases. Fig. 2 the results showed that the PI fill greatly reduces the PT FE composite wear; But in this test, within the limits of PI amount as the PI content increasing, the increase of the content of PI has a little influence on wear resistance of TEFLON composites. Fig. 3 the results showed that the PI filling percentage elongation of TEFLON composites basically decrease with the increase of content of PI. Fig. 4 shows that the result of the PI, the tensile strength of the filled TEFLON composites with PI decreased with the increase of adding amount of first, then with the PI amount increases with increasing (30% ~ 60%).

Fig. 5 and Fig. 6 show the friction coefficient and wear scar width of polystyrene fat filled TEFLON composites (2# samples) changes in load curves, respectively. It can be seen that polystyrene resin filled TEFLON composites (2# sample) the wear scar width increases as the load increases, the friction coefficient decreases with the increasing load.

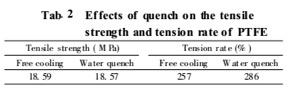

Tab. 2 show the pure TEFLON under two different conditions that free cooling and hardening of tensile strength and elongation of the test results. It can be seen that quench has little influence on tensile strength of TEFLON, but increase the elongation of TEFLON and TEFLON the crystallinity of the sample. Therefore, the crystallinity of TEFLON material size had little effect on the tensile strength, elongation increases with lower crystallinity.

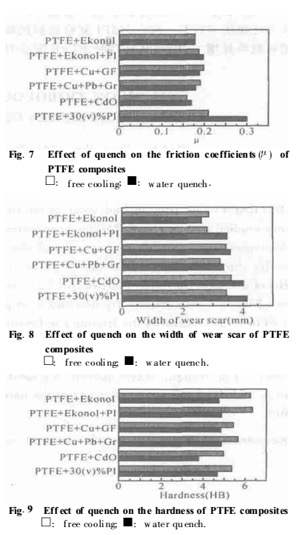

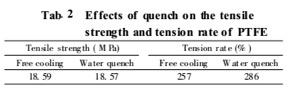

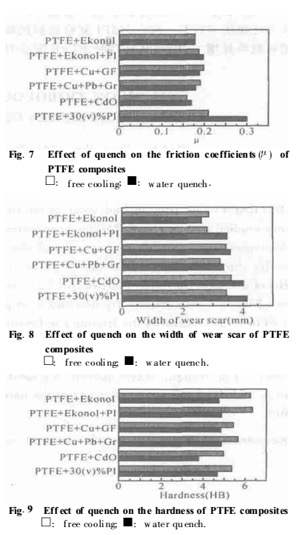

Fig. 7 to Fig. 9 respectively gives the quenching treatment on PT FE friction coefficient of the composite material, the influence of grinding crack width and hardness. Fig. 7 results show that quenching treatment make TEFLON + 30 (v) % PI the friction coefficient of the composite increased obviously, but for several other PT FE has little influence on friction coefficient of the composite material. Fig. 8 results show that, with the exception of polyphenyl grease filling PT FE composite samples (2 #), quenching the wear and tear in the other kinds of TEFLON composites increase, lower wear resistance. And Fig. 9 shows that the result of the quenching process are in different degree, reduce the PT FE hardness of the composite material.

Comprehensive Tab. 2 and Fig. 7 ~ Fig. 9, you can see that the result of the quenching process to lower crystallinity of TEFLON composites, which leads to its hardness decreases, and increase the elongation and abrasion (polyphenylene grease filling PT except FE abrasion resistance of the composite material).Quenching the PT FE + 30 (v) % PI the friction coefficient of the composite increased obviously, but for several other PT FE has little influence on friction coefficient of the composite material. Therefore, quenching treatment does not favor the comprehensive performance of TEFLON composites to improve.

If you want get to know more information about Teflon adhesive tape, please feel free to contact us system@corefrp.com. We will reply you soon. Thank you!