Teflon mesh belts are used in a wide range of applications. The belts can be applied to dryer mesh belt, sterilizer mesh belt, annealing furnace mesh belt, fryer mesh belt, sintering furnace mesh belt, instant noodle steamer mesh belt, etc., which are common application fields of Teflon mesh belts. So what are the safety regulations that should be observed during the use of Teflon mesh belts?

1. The Teflon mesh belt can be placed in the oven after all preparations are ready. A red light indicates that the box is heated. When the temperature reaches the controlled temperature, the red light turns off and the green light is on, and the temperature is started. In order to prevent temperature control failure, you must also look after it.

2. When placing the sample, it should be noted that the arrangement should not be too dense. The test piece should not be placed on the heat sink to avoid affecting the upward flow of hot air. It is forbidden to bake flammable, explosive, volatile and corrosive items.

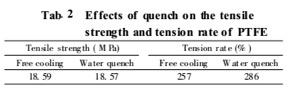

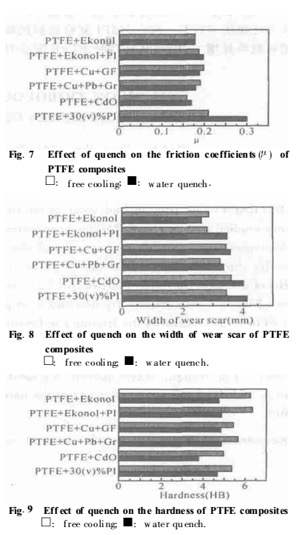

3. When it is necessary to observe the Teflon mesh belt sample in the working room, the outer door can be opened and observed through the glass door. However, it is better to open the door as little as possible to avoid affecting the constant temperature. Especially when working above 200 °C, opening the door may cause the glass door to quench and rupture.

4. In a blasted oven, the blower must be turned on during heating and constant temperature, otherwise it will affect the uniformity of the temperature of the working chamber and damage the heating element.

5. It should be placed indoors in a dry and level place to prevent vibration and corrosion.

6. When using the microwave conveyor belt, pay attention to the safe power supply, according to the power consumption of the oven power consumption device with sufficient capacity. Use enough power leads and have a good grounding wire.

7. Teflon mesh belt oven with electric contact mercury thermometer type thermostat should connect the two wires of the electric contact thermometer to the two terminals on the top of the box. In addition, an ordinary mercury thermometer is inserted into the exhaust valve. The thermometer in the exhaust valve is used to check the electrical contact mercury thermometer and the opening of the exhaust valve for observing the actual temperature in the tank. Adjust the electric contact mercury thermometer to the required temperature and tighten the screws on the steel cap to achieve the purpose of constant temperature. However, be careful not to screw the indicator iron out of the scale.

8. When using, the temperature should not exceed the maximum operating temperature of the oven.

9. To prevent burns, use special tools when handling samples.

10. After the Teflon mesh belt is finished, the power should be cut off in time to ensure safety.