Teflon conveyor belt is one of the key equipment for belt conveyors, So whether it can run smoothly is related to the operation of the entire conveyor.

Once the Teflon conveyor belt is deflected, it will accelerate the wear of the belt edge, shorten the service life, and seriously affect the production progress.

In addition to routine maintenance, installation accuracy is an important factor affecting the smooth operation of Teflon conveyor belts. Installation accuracy is mainly in conveyor belt and conveyor debugging of two aspects .

How do we judge which problem is caused by the deviation caused by the installation accuracy?

First, check whether the front and rear rollers of the conveyor are on the same center line and confirm whether they are parallel to each other;

Secondly, check whether the perimeter and diagonal of the two sides of the Teflon conveyor belt are equal.

When the Teflon conveyor belt is deflected to one side, the conveyor belt can be turned in the same direction. If the deviation is still to the original side, it is necessary to focus on checking the conveyor problem; if it is to the other side, it needs to pay attention to the situation of the Teflon conveyor belt.

Related terms in this article

Conveyor belt

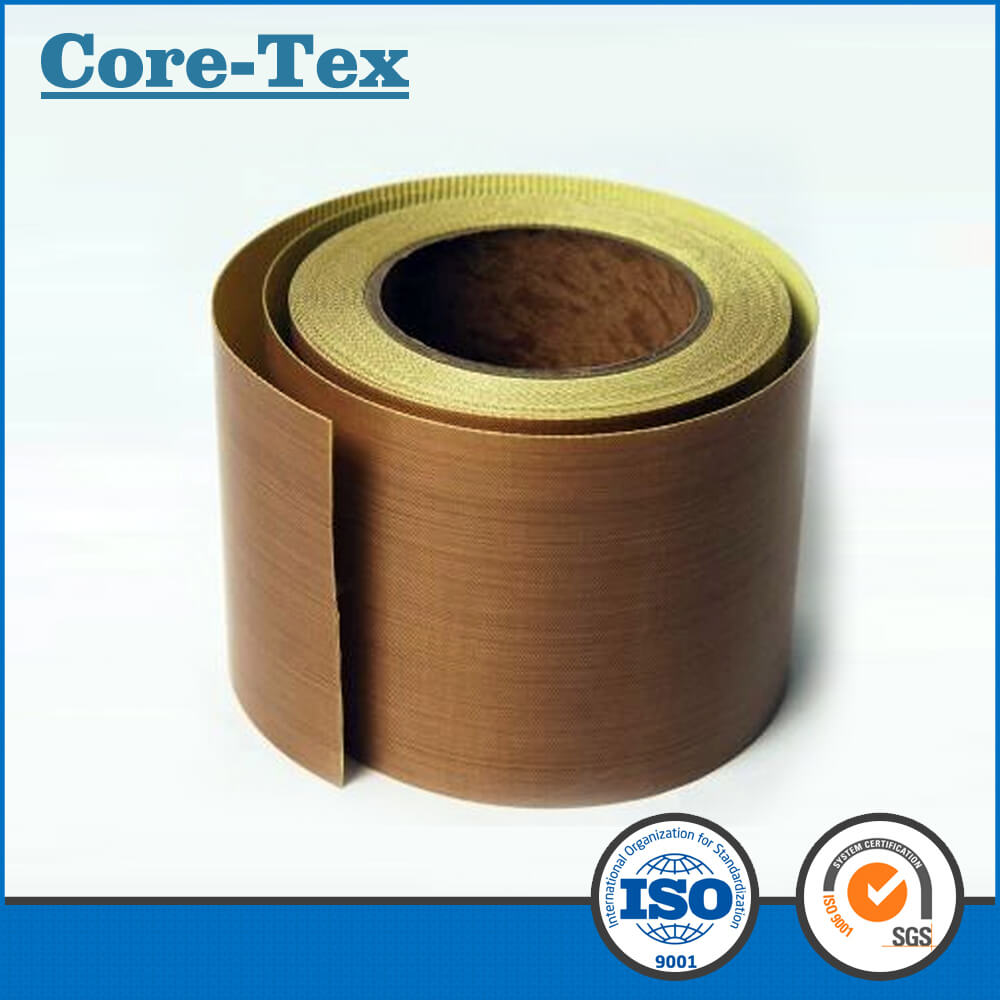

Product structure: This product is made of multi-layer hanging cotton canvas as the skeleton, and the surface is covered with good rubber material and vulcanized. Conveyor belt series products include ordinary cotton canvas conveyor belt and nylon (NN) conveyor belt (divided into NN-100 type, NN-150 type, NN-200 type, NN-250 type, NN-300 type, NN-350 type, NN-400 type), polyester (EP) belt (divided into EP-100 type, EP-150 type, EP-200 type, EP-250 type, EP-300 type, EP-350 type, EP-400 type) , large dip angle (corrugated rib) conveyor belt, skirt partition conveyor belt, endless conveyor belt, pattern conveyor belt(as?delivery?and?distribution of materials?with different?angle?sizes, shapes?and?height?requirements?are also?different patterns). Commonly used pattern conveyor belts such as: chevron pattern conveyor belt (herringbone conveyor belt including upper convex, lower concave herringbone conveyor belt), figure-8 shaped pattern conveyor belt, fishbone pattern conveyor belt, U-shaped pattern conveyor belt, cylindrical Pattern conveyor belt, pitting pattern conveyor belt, grass pattern conveyor belt, or according to user requirements), water stop belt, PVC or PVG whole core flame retardant belt; and can provide a variety of special performance conveyor belt (general Flame-retardant conveyor belt, heat-resistant conveyor belt, burning-resistant conveyor belt, high wear-resistant conveyor belt, acid-resistant conveyor belt, alkali-resistant conveyor belt, cold-resistant conveyor belt, oil-resistant conveyor belt, high-temperature conveyor belt, high-strength conveyor belt and food Conveyor belt, Teflon conveyor belt, stainless steel conveyor belt, chain conveyor belt, conveyor belt).

Teflon

Teflon was discovered in 1938 by chemist Dr. Roy J. Plunkett at DuPont’s Jackson Laboratory in New Jersey, USA: When he tried to make new chlorofluorocarbon refrigerants Tetrafluoroethylene is polymerized in a high pressure storage vessel (iron on the inner wall of the vessel becomes a catalyst for polymerization). DuPont obtained its patent in 1941 and in 1944 registered its trademark under the name “Teflon”. Subsequently, DuPont developed a series of products in addition to Teflon? PTFE resin, including Teflon; AF (amorphous fluoropolymer), Teflon; FEP (fluorinated ethylene propylene resin), Teflon; FFR (fluorine polymerization) Foam resin), Teflon; NXT (fluoropolymer resin), Teflon; PFA (perfluoroalkoxy resin) and so on. In 1954, Colette, the wife of French engineer Marc Gregoire, had a whimsy. She thought that if the non-stick material “Teflon” that her husband used to apply on the fishing line which to prevent knotting could be used on the frying pan, the effect must be good. The “non-stick” that saved countless modern housewives was born.

Conveyor

According to the operation mode, the conveyor can be divided into: belt conveyor, screw conveyor, bucket elevator, roller conveyor, metering conveyor, chain conveyor, mesh belt conveyor and chain conveyor.