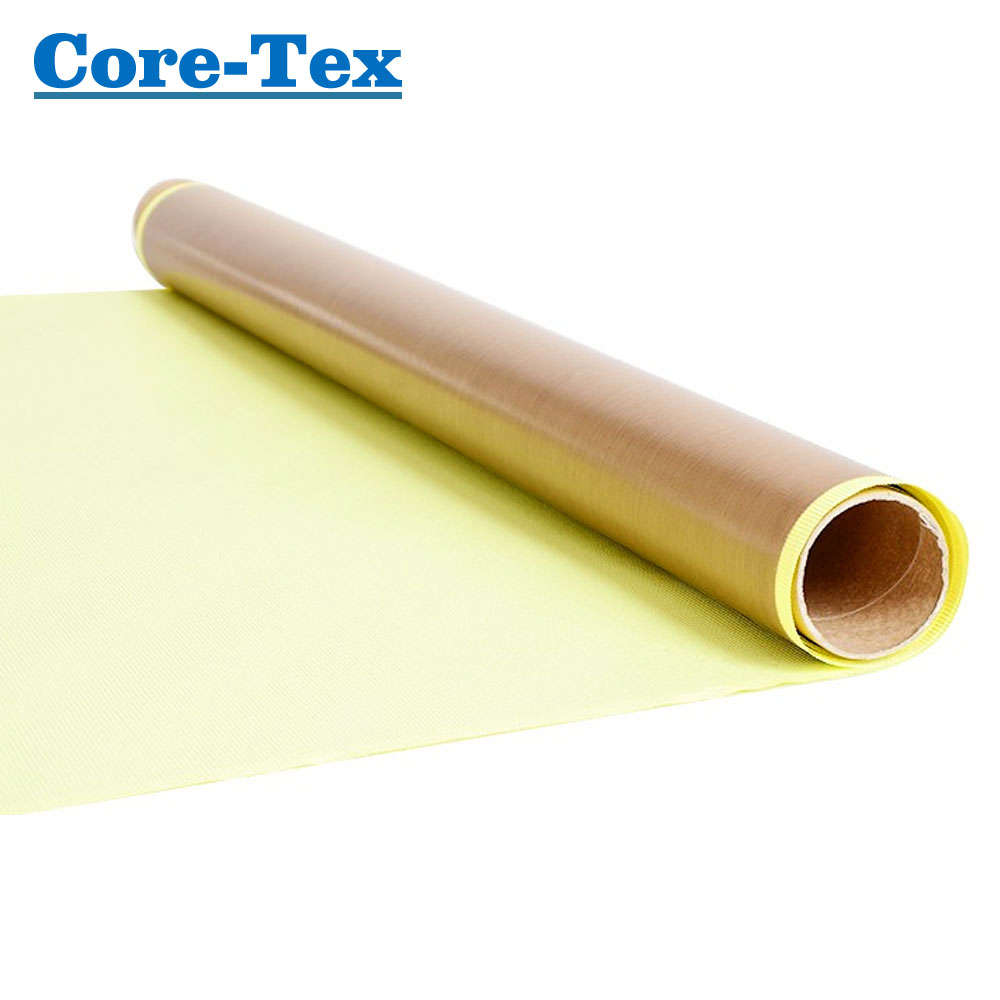

PTFE (Teflon) high temperature cloth is a high-performance, multi-purpose composite material new product which is made of polytetrafluoroethylene emulsion and impregnated with high-performance glass fiber cloth.

PTFE (Teflon) high temperature cloth is commonly known as release cloth in the demoulding industry, and its characteristics of high anti-sticking, high temperature resistance, low friction and anti-corrosion. The release cloth has the following advantages:

1. The mold release is complete, the product qualification rate is highly improved, the scrap rate is greatly reduced, and the cost is saved.

2.The surface is uniform, flat, high gloss, so that the appearance of the mold is very grade.

3. No environmental pollution, saving cost, avoiding the rubber vulcanization and bonding.

4. No rubber particles remain on the surface of the mold, so cleaning process is not required, thus shortening the demolding process, improving production efficiency, reducing losses, and reducing production costs.

5. Durable (5,000 times).

The main thickness: 0.11mm、0.13mm、0.18mm.

The main color: brown, white and black.

Main performance characteristics:

1.Temperature resistance: up to 260℃. After 200 days at 250℃, the strength and weight of the belt are kept the same

2.Non stick: not easy to stick any substance. It is easy to clean, all adhesive substances such as paste, resin, paint, etc. can be easily removed.

3. Chemically resistance: resistant to strong acids, alkalis, aqua regia and various organic solvents.

4.Low friction coefficient (0.05-0.1).

5.The light transmittance is 6-13%.

6.With high insulation properties, the dielectric constant is 2.6

7.Good dimensional stability (extension coefficient less than 5‰) and high strength.

8. Non-toxic.

9.Fire retardant.

23

23