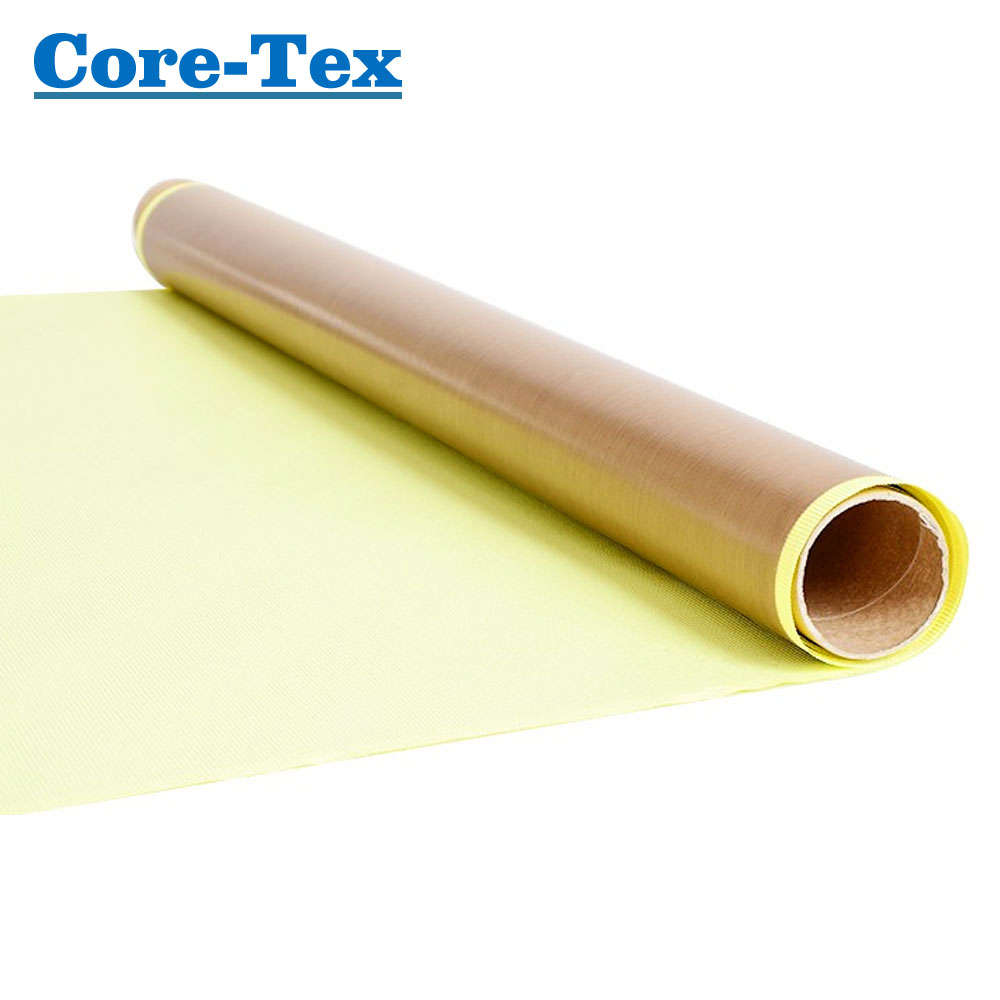

PTFE tape, also known as Teflon tape, is a type of adhesive tape made from polytetrafluoroethylene (PTFE). It is known for its high temperature resistance and low friction properties, making it a popular choice in various industries.

PTFE tape can withstand a wide range of temperatures, ranging from -268°C to 260°C (-450°F to 500°F). This temperature resistance is due to the unique properties of PTFE, which is an extremely stable and non-reactive material. PTFE does not melt or burn, and it remains stable even at high temperatures.

Due to its temperature resistance, PTFE tape is commonly used in applications that involve high temperatures. For example, it is used in the aerospace industry for sealing and insulating electrical wires and components in aircraft engines, where temperatures can reach over 200°C (392°F). It is also used in the automotive industry for sealing and insulating components in engines and transmissions that are exposed to high temperatures.

In addition to its temperature resistance, PTFE tape also has excellent chemical resistance and electrical insulation properties. It is resistant to most chemicals, including acids, bases, and solvents, and it has a high dielectric strength, making it an excellent insulator.

PTFE tape is available in different thicknesses and widths to suit different applications. It can be used as a sealant for pipes and fittings, as well as a gasket material in various industries. It is also commonly used in the food industry for sealing and wrapping food products, as it is non-toxic and non-reactive.

PTFE tape is a versatile and highly temperature-resistant material that is commonly used in various industries. Its unique properties make it an excellent choice for applications that require high temperature resistance, chemical resistance, and electrical insulation.

If you need a reliable and durable tape that can withstand high temperatures, PTFE tape is definitely worth considering.

23

23